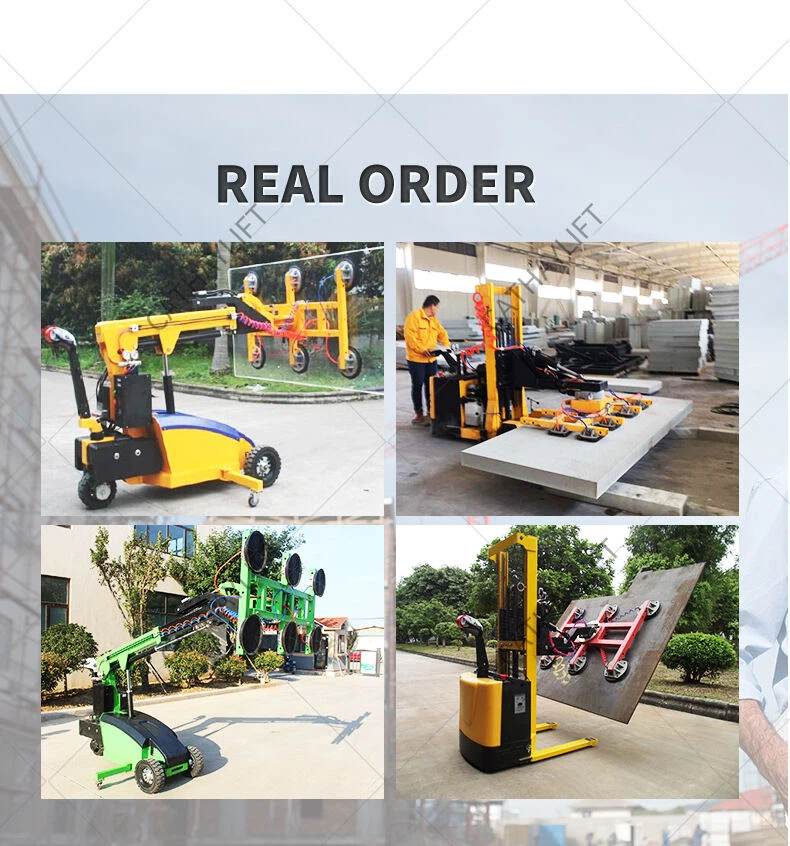

Vacuum Lifter For Sheet Metal

The vacuum lifter for sheet metal is a specialized piece of equipment used for handling, loading, and unloading various types of plates, glass, and other materials. It is designed to be versatile, efficient, and safe, with features such as automatic pressure control, safety monitoring, and multi-functional controls. The lifter works by using suction cups to lift and hold the materials securely in place while they are being transported or manipulated.

|

Model |

XC-H400(4) |

XC-H400(6) |

XC-H600(6) |

XC-H600(8) |

|

|

Rated Load Capacity |

400kgs |

600kgs |

|||

|

Safe Load Capacity |

200kgs |

300kgs |

|||

|

Lifting Height |

1500mm |

1500mm |

|||

|

QTY of Suction Caps |

4pcs |

6pcs |

6pcs |

8pcs |

|

|

Cap Diameter |

Ø300mm |

Ø300mm |

|||

|

Plate Size (customized) |

1220x1830mm |

2440x1830mm |

|||

|

Load Center |

650mm |

950mm |

|||

|

Drive Motor |

24V/500W |

24V/700W |

|||

|

Hydraulic Motor |

24V/2000W |

24V/2000W |

|||

|

Battery |

2x12V/70Ah |

2x12V/100Ah |

|||

|

Charger |

24V/10A |

24V/15A |

|||

|

Model |

XC-H800(8) |

XC-H800(10) |

XC-H800(8) |

XC-H800(10) |

|

|

Rated Load Capacity |

800kgs |

800kgs |

|||

|

Safe Load Capacity |

400kgs |

400kgs |

|||

|

Lifting Height |

1500mm |

2500mm |

|||

|

QTY of Suction Caps |

8pcs |

10pcs |

8pcs |

10pcs |

|

|

Cap Diameter |

Ø300mm |

Ø300mm |

|||

|

Plate Size (customized) |

3660x2440mm |

3660x2440mm |

|||

|

Load Center |

1250mm |

1250mm |

|||

|

Drive Motor |

24V/900W |

24V/900W |

|||

|

Hydraulic Motor |

24V/2000W |

24V/2000W |

|||

|

Battery |

2x12V/160Ah |

2x12V/160Ah |

|||

|

Charger |

24V/20A |

24V/20A |

|||

Products Details

Why choose our vacuum lifter?

Versatility: The lifter can handle a variety of materials, including plates and glass, making it suitable for various applications.

No front fork feet: The absence of front fork feet makes the lifter unaffected by front trays, tripods, and other obstacles, making it more convenient to carry.

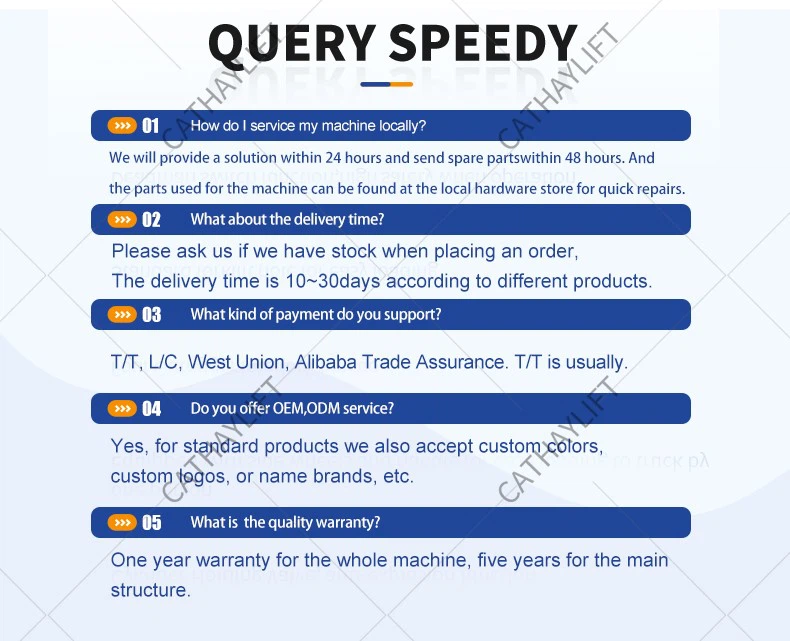

Safety: The lifter has its own power supply and automatically adjusts and controls the working pressure using European safety standards. It also has a double-pipeline system for safety monitoring to prevent accidents.

Environmental friendliness: The lifter is designed to be environmentally friendly and efficient, making it easy to operate.

Multi-functional: The lifter has several functions, including electric front and rear travel control, electro-hydraulic lifting, electric side shift (optional), motorized forward or backward tilt, and

plane 360 rotation.

Portability: The lifter is small in appearance, making it easy to enter the elevator. Additionally, different specifications (sizes) of walking wheels can be selected according to the requirements of different users and occasions.

Product categories: The lifter comes in various product categories, including walking type economical type, standard type folding pedal standing type, counterweight type, driving cabin steering wheel control type, etc.

Configuration: The lifter comes with an intelligent ten-level power display table, a multi-function control handle, a large-capacity battery pack, and a smart microcomputer charger.

How to maintain and replace hydraulic oil.

Hot Tags: vacuum lifter for sheet metal, Vacuum Lifter, Vacuum Glass Lifter, Electric Vacuum Glass Lifter, Glass Lifter, Small Glass Lifting Suction Cups, Large Glass Lifting Suction Cups